Advanced Anti-Corrosion Protection for Submersible and Irregular Marine Applications (Ref-MPF57G)

SUBMERSIBLE+ is a technically advanced, single-sided protective tape designed to provide robust corrosion protection for submerged or buried components—especially those with irregular shapes. Ideal for submersible pumps, electronics, prop shaft bearings, and subsea cable repairs, it simplifies application by replacing the need for multiple traditional layers.

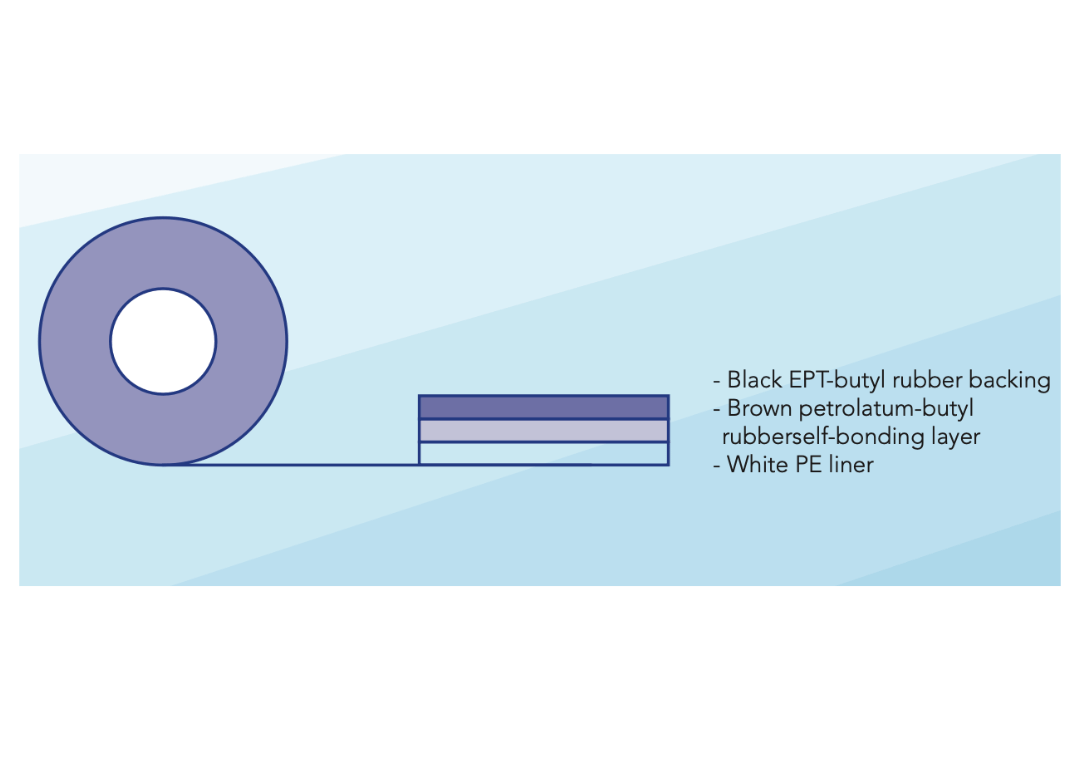

With its triple-layer composition—black EPT-butyl rubber backing, brown petrolatum-butyl rubber bonding layer, and white PE liner—SUBMERSIBLE+ delivers perfect watertight sealing, even in the most complex marine environments.

Request Product Information

Key Benefits

Complete Watertight Sealing

Provides perfect environmental protection for underwater components and connections.

Superior Corrosion Resistance

Multi-layer construction creates a powerful barrier against rust and corrosion in marine environments.

Exceptional Conformability

Flexible construction adapts perfectly to complex shapes and irregular components.

Three-in-One System

Replaces conventional multi-layer approaches with a single, comprehensive protection solution.

Technical Specifications

Advanced protection for submersible marine applications

| Use Case | Corrosion protection for submersible or buried marine components |

| Weatherability/UV Resistance | Up to 6 months |

| Colour | Black / Brown / White (multi-layer) |

| Ease of Application | Skilled application recommended |

| Watertightness | Excellent – full environmental sealing |

| Adhesion | Very strong, even on irregular surfaces |

| Rust Protection | High-performance anti-corrosion barrier |

| Pre-Punchable | Easy to process and customise |

Application Areas

Submersible Pumps

Protects electrical connections and mechanical components on bilge pumps and other submersible equipment.

Cable Connections

Seals and protects critical electrical and communication cable junctions from water ingress and corrosion.

Prop Shaft Bearings

Prevents corrosion and provides effective sealing for propulsion system components exposed to harsh underwater conditions.

Marine Electronics

Safeguards sensitive electronic connections from moisture, salt, and environmental damage in underwater applications.

Application Information

Proper Application For Best Results

-

1

Thorough Surface Preparation

Clean the component thoroughly to remove all dirt, oil, moisture, and contaminants. For metal surfaces, remove any loose rust or scale. A clean, dry surface is essential for optimal adhesion.

-

2

Measure and Cut

Measure the required length with approximately 50% overlap for each wrap. Cut the tape cleanly with scissors or a sharp knife, keeping the release liner in place until ready to apply.

-

3

Spiral Wrapping Technique

Remove the release liner and apply with firm pressure, stretching slightly (10-15%) as you wrap. Use a spiral technique with 50% overlap between layers. For irregular shapes, apply in sections, working from the center outward.

-

4

Ensure Complete Sealing

Apply firm pressure across the entire surface to ensure proper adhesion and eliminate air pockets. For critical applications, finish with an additional layer where extra protection is needed.

Frequently Asked Questions

-

What makes SUBMERSIBLE+ different from standard marine tapes?

SUBMERSIBLE+ features a unique triple-layer construction specifically engineered for underwater applications. Unlike standard marine tapes, it combines a black EPT-butyl rubber backing, a brown petrolatum-butyl rubber bonding layer, and a white PE liner in a single product. This specialized design replaces traditional multi-step application processes that typically require primers, fillers, and outer protection layers. The petrolatum-butyl rubber bonding layer provides superior corrosion protection and water displacement properties, while maintaining flexibility even in cold water conditions. This all-in-one approach significantly reduces application time while delivering superior protection in challenging submersible environments.

-

At what depth can SUBMERSIBLE+ be effectively used?

SUBMERSIBLE+ has been tested and performs reliably at depths of up to 40 meters (approximately 130 feet) in both freshwater and saltwater environments. Beyond this depth, performance should be evaluated case by case. The tape maintains its adhesive properties and protective capabilities under the increased pressure at these depths due to its unique formulation.

-

How long can SUBMERSIBLE+ remain effective underwater?

When properly applied according to our guidelines, SUBMERSIBLE+ provides effective protection in permanent underwater installations for up to 5 years, though this can vary based on environmental conditions. In harsh marine environments with high biological activity, strong currents, or extreme temperature variations, we recommend inspection after 3 years. The tape's multi-layer construction creates a durable barrier that resists degradation from saltwater, biological growth, and moderate UV exposure when occasionally exposed during low tides.

-

Is specialized training needed for application?

While SUBMERSIBLE+ is designed to be more user-friendly than traditional multi-layer systems, we do recommend that application be performed by personnel with some experience in marine maintenance or protection systems. The tape's performance is directly related to proper application technique, particularly when dealing with complex shapes or critical underwater components.

Request Product Information

Get detailed specifications, pricing, and application guidance for SUBMERSIBLE+ (Ref-MPF57G).