High-Performance Corrosion Protection Tape

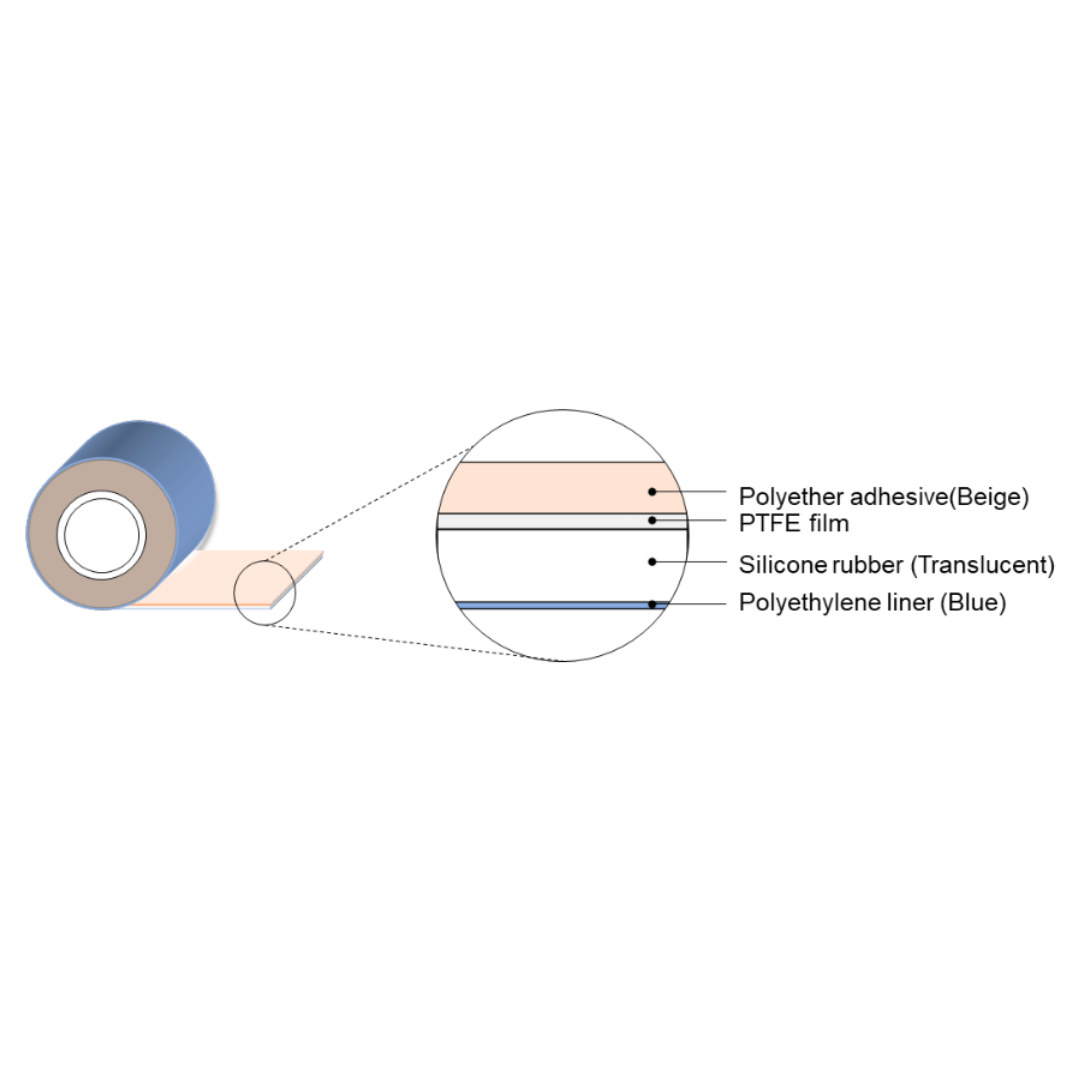

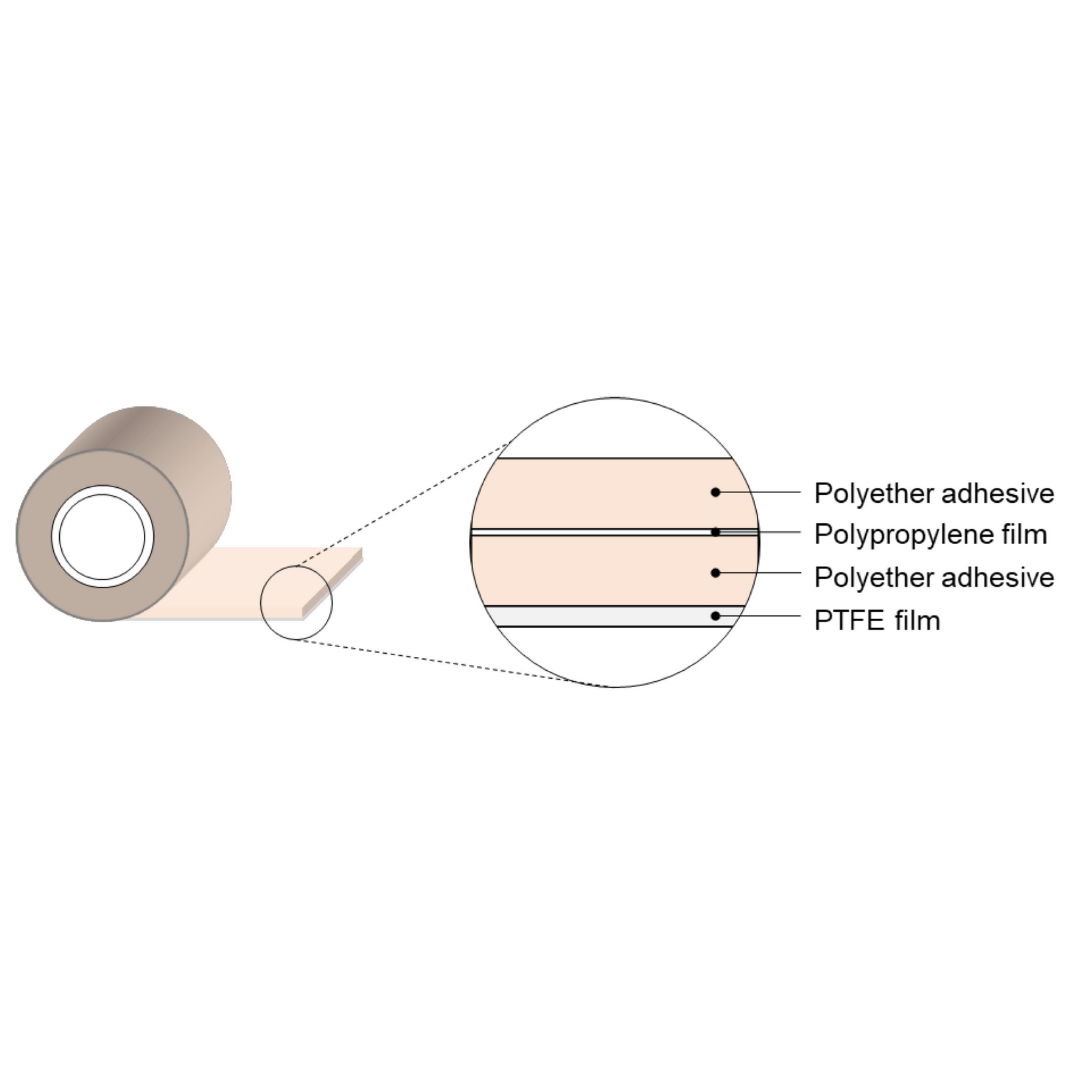

MARINE-SEAL (Ref-SC140) is a single-sided protective tape developed for corrosion resistance in high-moisture areas of marine vessels, such as beneath floorboards, in galleys, lavatories, and along door sills. Its strong adhesion to a wide range of substrates and smooth PTFE backing ensure fast, efficient installation and reliable long-term protection.

Tested to withstand 3,000 hours of salt spray exposure, MARINE-SEAL provides lightweight, durable coverage that helps extend vessel life while remaining easy to remove during inspections or servicing. It meets both REACH and RoHS standards and is free from halogens and other environmentally harmful materials.

Request Product Information

Key Benefits

Corrosion Prevention

Engineered specifically for subfloor and structural corrosion protection in marine environments.

Easy Application

Smooth PTFE backing for fast, efficient installation and clean, residue-free removal.

Lightweight Design

Contributes to better fuel efficiency while providing robust protection.

Extensive Testing

Withstands 3,000-hour salt spray exposure for proven long-term durability.

Technical Specifications

Engineered for peak performance in demanding marine environments

| Use Case | Corrosion protection for underfloor and structural components |

| Material | Single-sided PTFE-backed adhesive tape |

| Weatherability | Tested for 3,000-hour salt spray resistance |

| Flame Retardant | Yes – environmentally friendly system |

| Residue After Removal | None |

| Ease of Application | Excellent – designed for fast, efficient installation |

| Adhesion | Strong – bonds to a wide range of substrates |

| Compliance | REACH & RoHS |

| Eco Features | Halogen-free, no antimony trioxide |

| Available Sizes | Custom widths available on request |

Application Areas

Below Floorboards

Protects support structures from moisture and corrosion in high-humidity areas beneath floorboards.

Galley Spaces

Provides reliable protection in food preparation areas where water exposure is common.

Lavatories

Guards against moisture damage in bathroom areas with high condensation and water exposure.

Door Sills

Protects transition areas between spaces where water intrusion is most likely to occur.

Application Information

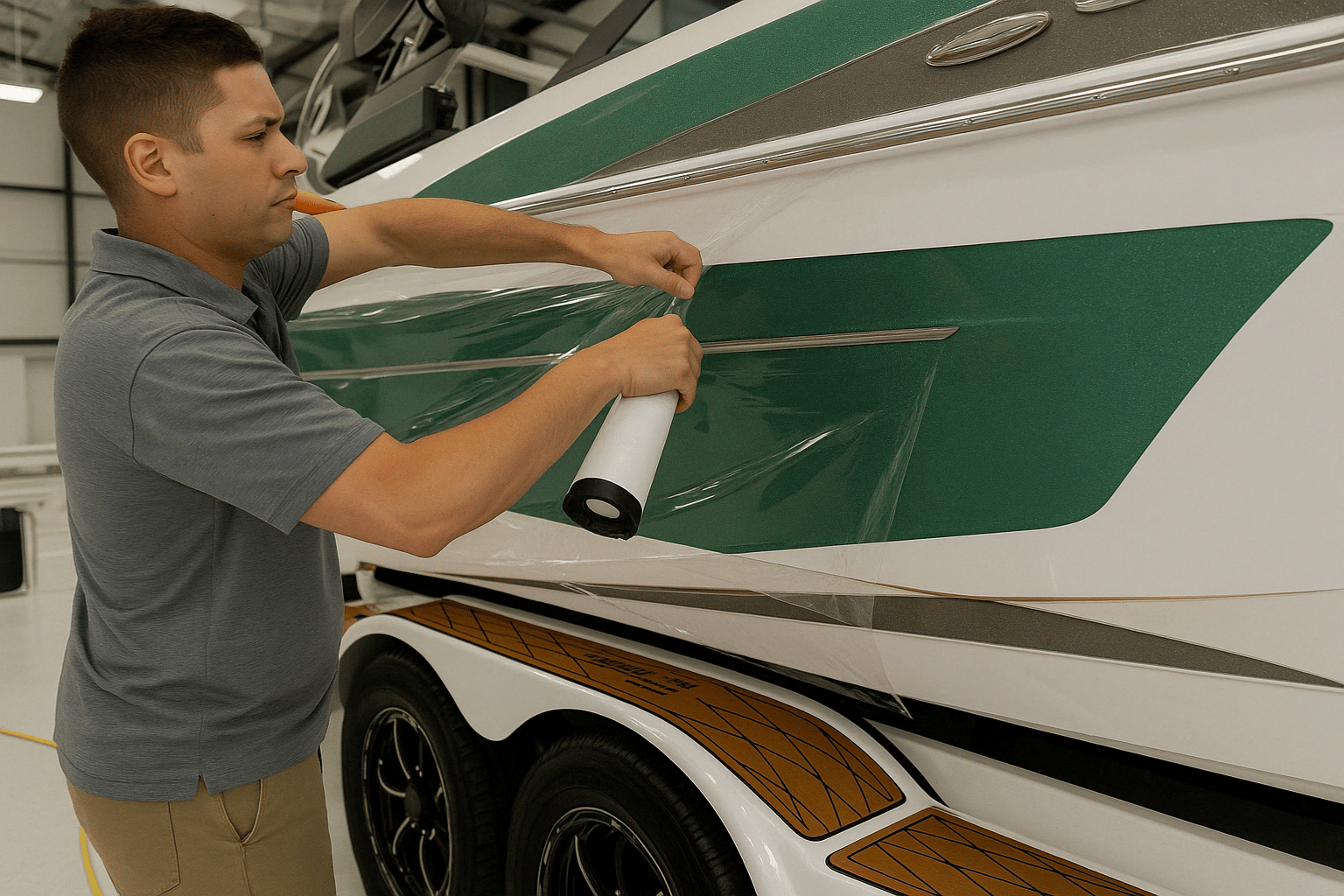

Proper Application For Best Results

-

1

Surface Preparation

Ensure the surface is clean, dry and free from contaminants before application.

-

2

Measure & Cut

Cut the MARINE-SEAL tape to size with a 5-10mm overlap where appropriate.

-

3

Apply The Tape

Remove backing while applying, using a squeegee to eliminate air bubbles.

-

4

Secure The Edges

Apply firm pressure to edges to ensure proper sealing and prevent moisture ingress.

Frequently Asked Questions

-

How long will MARINE-SEAL last in a marine environment?

MARINE-SEAL has been tested to withstand 3,000 hours of salt spray exposure, which typically translates to several years of protection in most marine environments. However, regular inspection is recommended, particularly in extreme conditions.

-

Can MARINE-SEAL be applied to damp surfaces?

For optimal adhesion and performance, we recommend applying MARINE-SEAL to clean, dry surfaces. Moisture trapped between the tape and substrate can compromise adhesion. If the area is damp, thoroughly dry it before application.

-

Is MARINE-SEAL suitable for exterior hull applications?

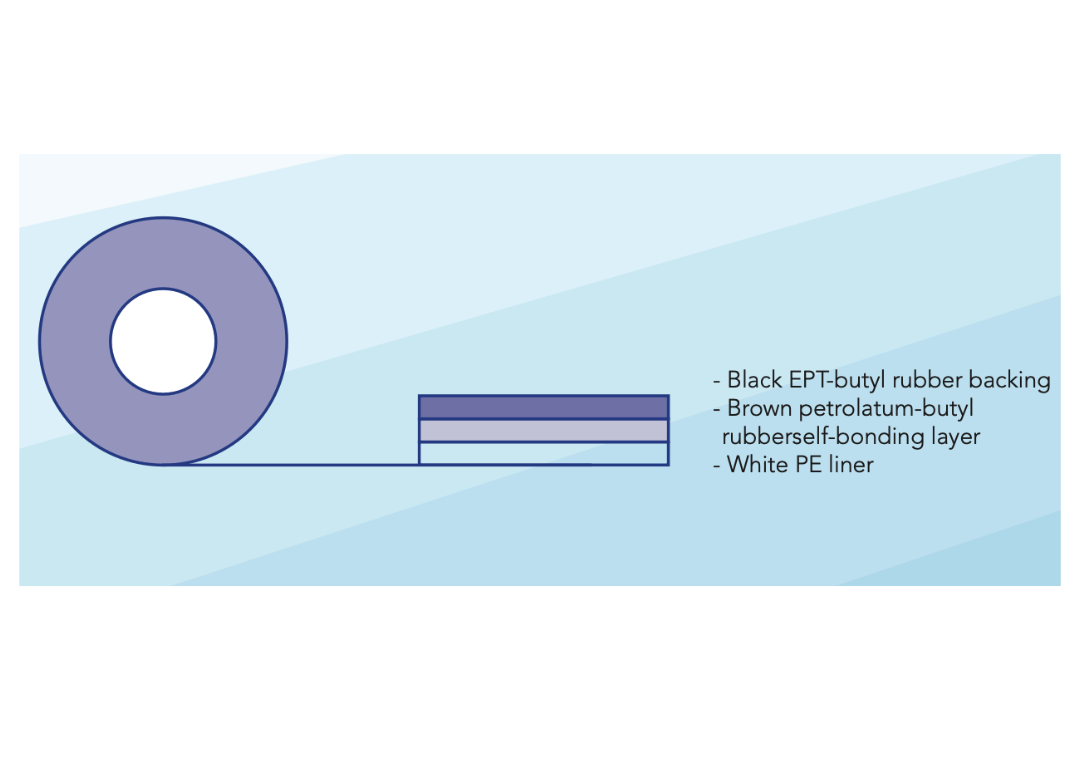

MARINE-SEAL is primarily designed for interior structural protection. For exterior hull protection, we recommend our Hullguard product range, which is specifically engineered for external surfaces and submersion conditions.

-

Will MARINE-SEAL leave residue when removed?

No, MARINE-SEAL is designed for clean removal without leaving residue, even after extended periods. This makes it ideal for areas that require periodic inspection or maintenance.

Request Product Information

Get detailed specifications, pricing, and application guidance for MARINE-SEAL.