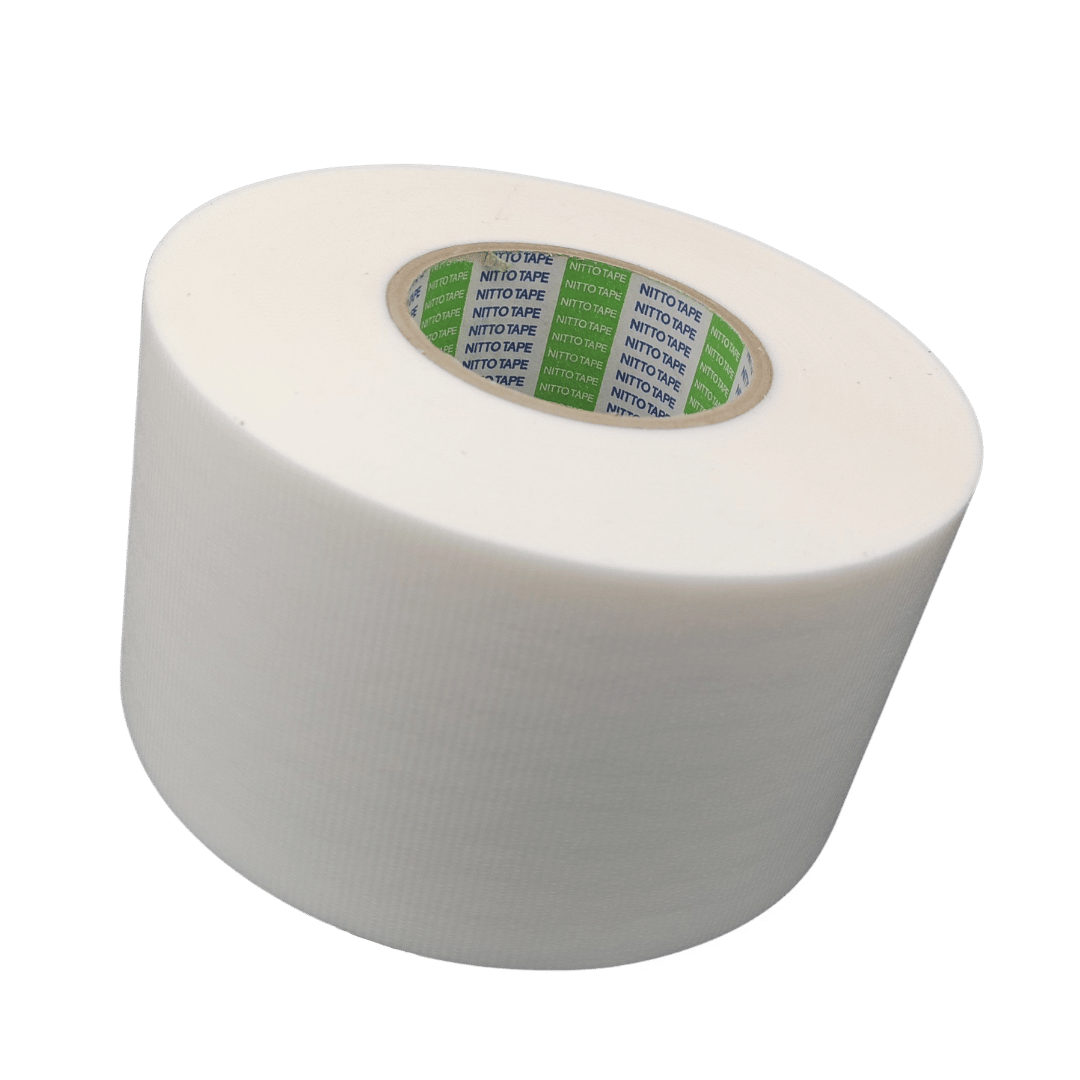

Non-Slip Safety Tapes for Marine & Industrial Surfaces

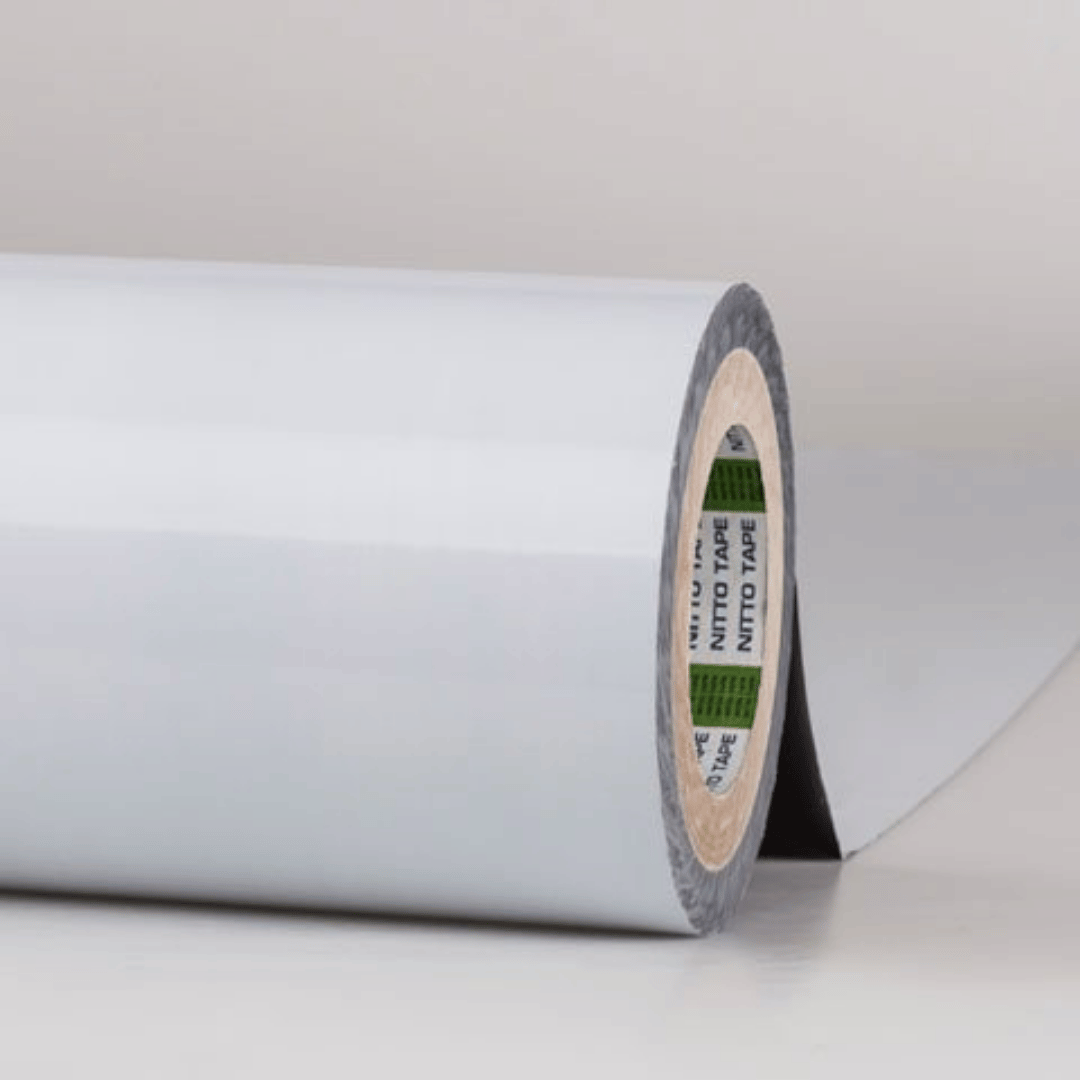

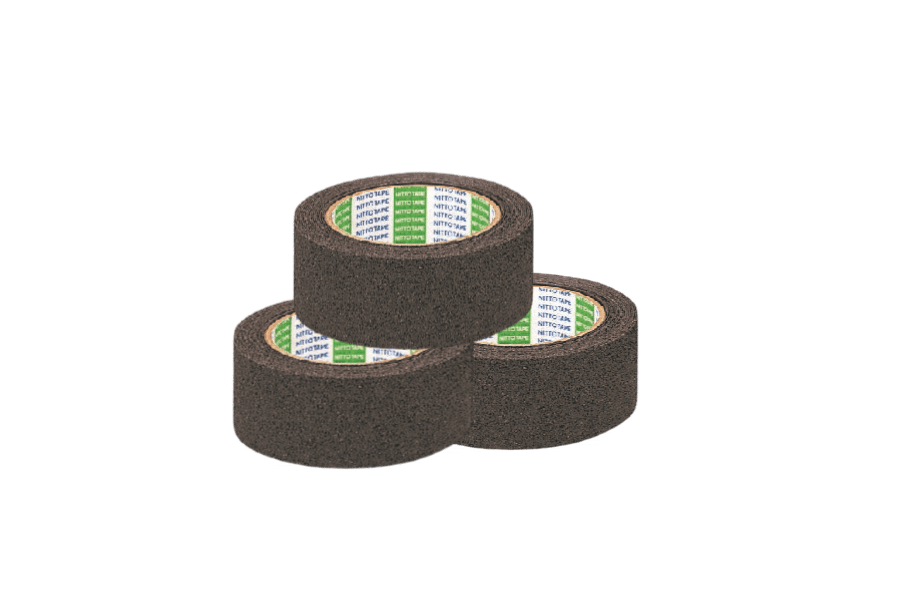

Our Nitto Anti-Skid Tapes are designed with safety as the top priority—helping reduce the risk of slips and falls on stairs, walkways, and sloped surfaces, both on land and at sea. These durable tapes come in two material options to suit different types of surfaces:

MPF117 (Polyester substrate): Ideal for flat, smooth surfaces, offering a dependable non-slip finish for steps, ramps, and more.

MPF127 (Aluminium-foil substrate): Designed for irregular or contoured surfaces, the flexible aluminium backing conforms to uneven shapes and maintains excellent grip over time.

Perfect for high-traffic areas such as decks, companionways, and dock entries, both versions are available in a range of widths and are easy to apply.

Request Product Information

Key Benefits

Enhanced Safety

Reduces slip hazards in wet, oily, or high-traffic areas to prevent accidents and injuries.

Weather Resistant

Maintains grip performance in wet conditions and withstands marine environmental exposure.

Versatile Application

Two substrate options ensure optimal adhesion on both smooth and irregular surfaces.

Long-Lasting

Durable construction stands up to heavy foot traffic and frequent use without degrading.

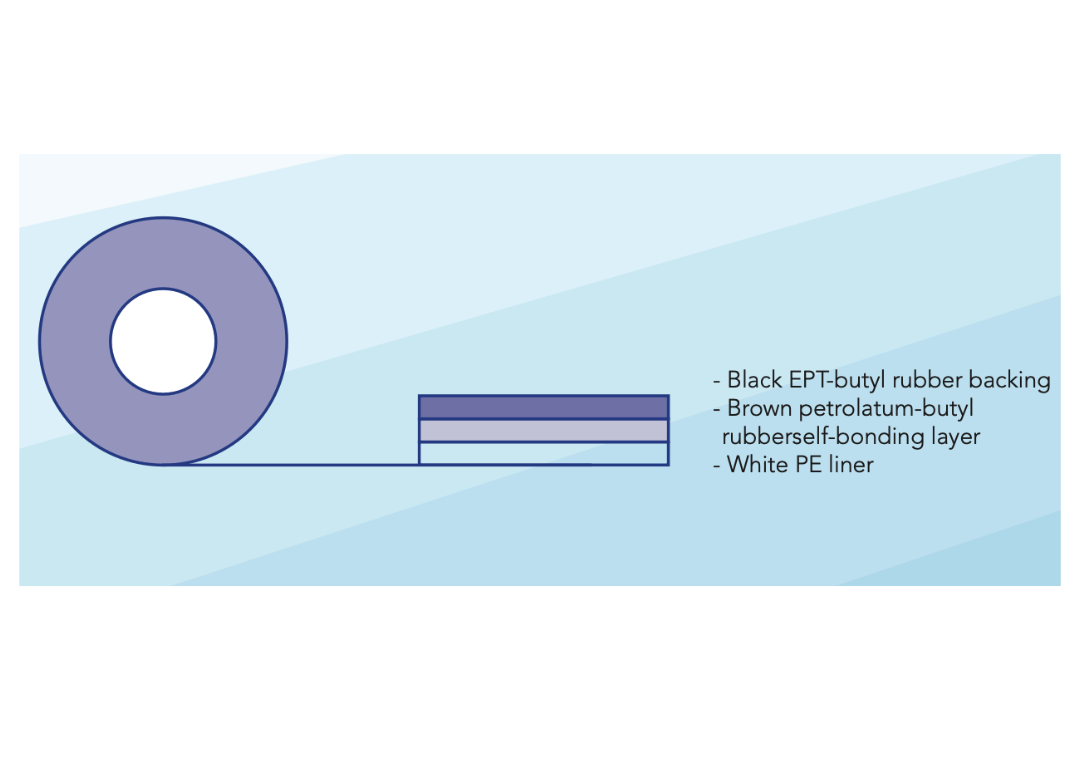

Technical Specifications

Non-slip safety tapes for marine and industrial applications

| Use Case | Anti-slip protection in marine, commercial, and industrial settings |

| Substrates | • MPF117 – Polyester, for smooth surfaces • MPF127 – Aluminium foil, for contoured or uneven surfaces |

| Weatherability/UV Resistance | Up to 2 months |

| Colour | Black |

| Ease of Application | Very Good |

| Residue After Removal | Minimal |

| Durability | Excellent, even under heavy foot traffic |

| Available Sizes | Various widths on request |

Application Areas

Marine Decking

Provides slip resistance on boat decks, companionways, and boarding areas that are frequently exposed to water.

Stairways & Steps

Creates safer walking surfaces on steps, stairways, and ladders in marine and industrial environments.

Work Areas

Improves safety in shipyard work zones, maintenance areas, and around machinery where slip hazards exist.

Ramps & Inclines

Enhances traction on docks, gangways, and sloped surfaces where additional grip is essential.

Application Information

Proper Application For Best Results

-

1

Surface Preparation

Clean the application surface thoroughly to remove dirt, oil, grease, and moisture. For best results, use isopropyl alcohol for final cleaning and allow to dry completely.

-

2

Measure & Cut

Measure and cut the tape to desired length, adding approximately 5% extra to account for any mistakes. Round all corners to prevent edge lifting.

-

3

Apply With Pressure

Remove the backing and apply the tape starting from one end, gradually pressing down firmly as you go. Use a rubber roller to ensure maximum contact with the surface.

-

4

Final Setting

For optimal adhesion, apply heavy pressure across the entire surface after application. Allow 24 hours for the adhesive to fully set before exposing to heavy traffic or wet conditions.

Frequently Asked Questions

-

How do I choose between MPF117 and MPF127?

The choice depends on your application surface. MPF117 with polyester substrate works best on smooth, flat surfaces like polished decking, fiberglass, or metal floors. MPF127 with aluminum foil backing is ideal for irregular, textured, or contoured surfaces where conformability is essential, such as diamond plate, textured fiberglass, or rounded steps. For surfaces with moderate texture, either option may work, though MPF127 generally provides better adhesion on uneven surfaces due to its flexibility.

-

How long can I expect the anti-slip properties to last?

The anti-slip performance depends on traffic levels and environmental conditions. In typical marine applications with moderate foot traffic, you can expect 6-12 months of effective slip resistance. Heavy traffic areas may see reduced performance after 3-6 months. The adhesive bond typically lasts longer than the non-slip surface itself. We recommend periodic inspection and replacement when the abrasive surface begins to show significant wear to maintain safety standards.

-

Are these tapes resistant to chemicals and cleaning agents?

Our Anti-Skid tapes demonstrate good resistance to most common marine cleaning products, freshwater, and saltwater exposure. They can withstand occasional contact with mild detergents, soaps, and diluted cleaning solutions. However, prolonged exposure to harsh solvents, strong acids, or petroleum-based products can degrade the adhesive over time. When cleaning areas with Anti-Skid tape applied, we recommend using mild cleaning agents and avoiding pressure washing directly on the tape edges, which could accelerate lifting.

-

Can these tapes be removed without damaging surfaces?

Yes, both MPF117 and MPF127 are designed to be removable with minimal surface impact when properly removed. For best results, we recommend heating the tape slightly with a heat gun (on low setting) or hair dryer to soften the adhesive, then slowly peeling back at a 45-degree angle. Some minor adhesive residue may remain depending on the installation duration and surface type, but this can typically be removed with adhesive remover or isopropyl alcohol. For delicate surfaces, test any cleaning solution in an inconspicuous area first.

Request Product Information

Get detailed specifications, pricing, and application guidance for ANTI-SKID safety tapes.