High-Performance Moisture Barrier for Marine Floor Panels

BARRIER TAPE (Ref-11611MB) is a robust 16 mil polyurethane moisture barrier tape with a 2 mil adhesive layer, engineered to prevent water ingress and corrosion on vessel floor panels. Ideal for use in high-moisture environments, it provides an essential layer of protection during maintenance or construction.

Its two-part application approach first seals panel seams and then covers the entire floor panel, forming a complete barrier against liquid intrusion. Flame retardant and highly resistant to chemicals, it's designed for harsh marine conditions.

With exceptional puncture and tear resistance, low water vapour transmission, and high elongation, this tape delivers durability and flexibility in active marine workspaces.

Request Product Information

Key Benefits

Comprehensive Moisture Barrier

Creates a long-lasting moisture barrier on vessel floor panels to prevent water damage and corrosion.

Two-Step Application

Strategic application process first seals panel seams, then provides full-panel coverage for complete protection.

Flame Retardant

Built-in flame retardant properties enhance safety in critical marine installations.

Durable Construction

Exceptional puncture and tear resistance ensures continued protection in high-traffic areas.

Technical Specifications

Engineered for superior moisture protection in marine environments

| Use Case | Moisture barrier for floor panels and high-moisture areas |

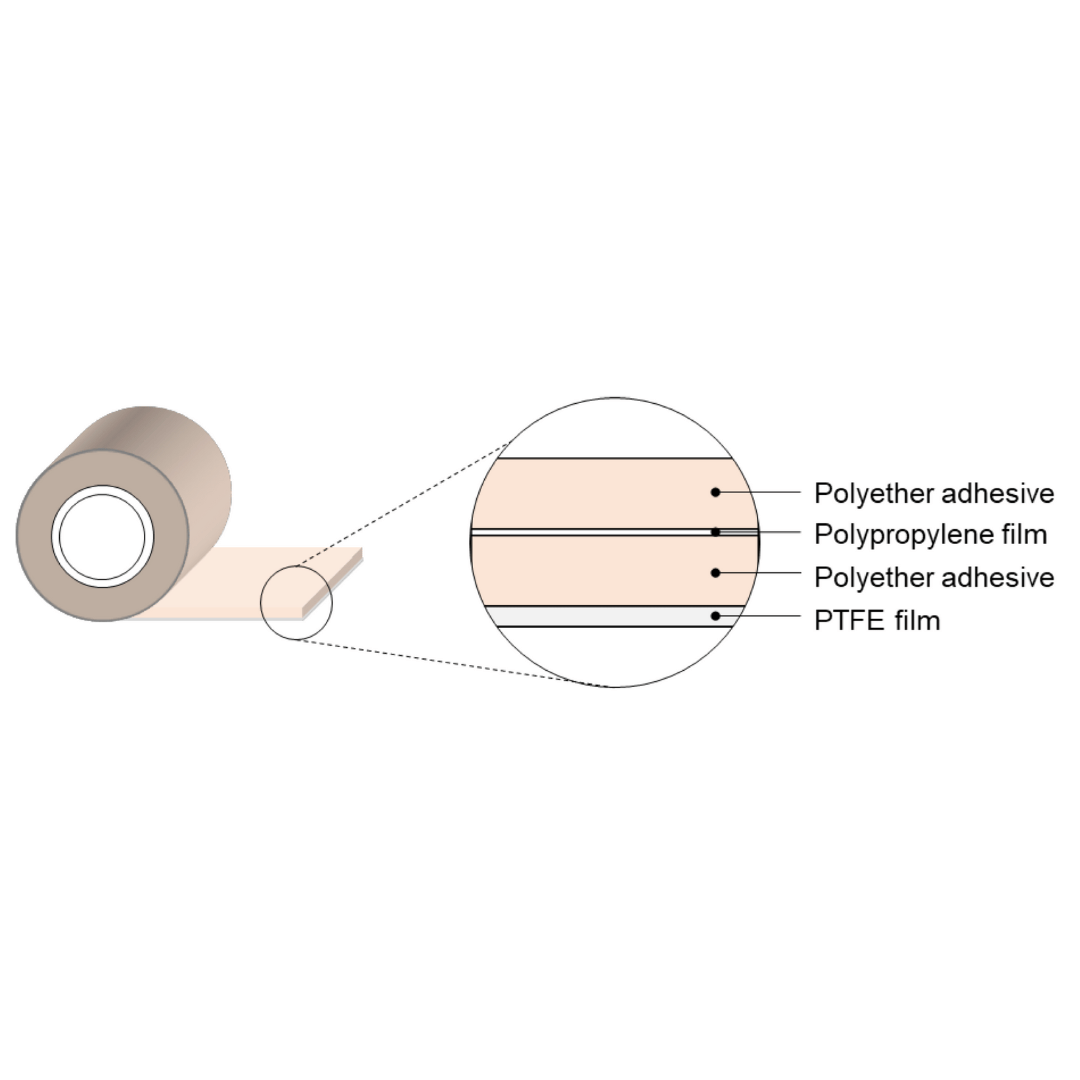

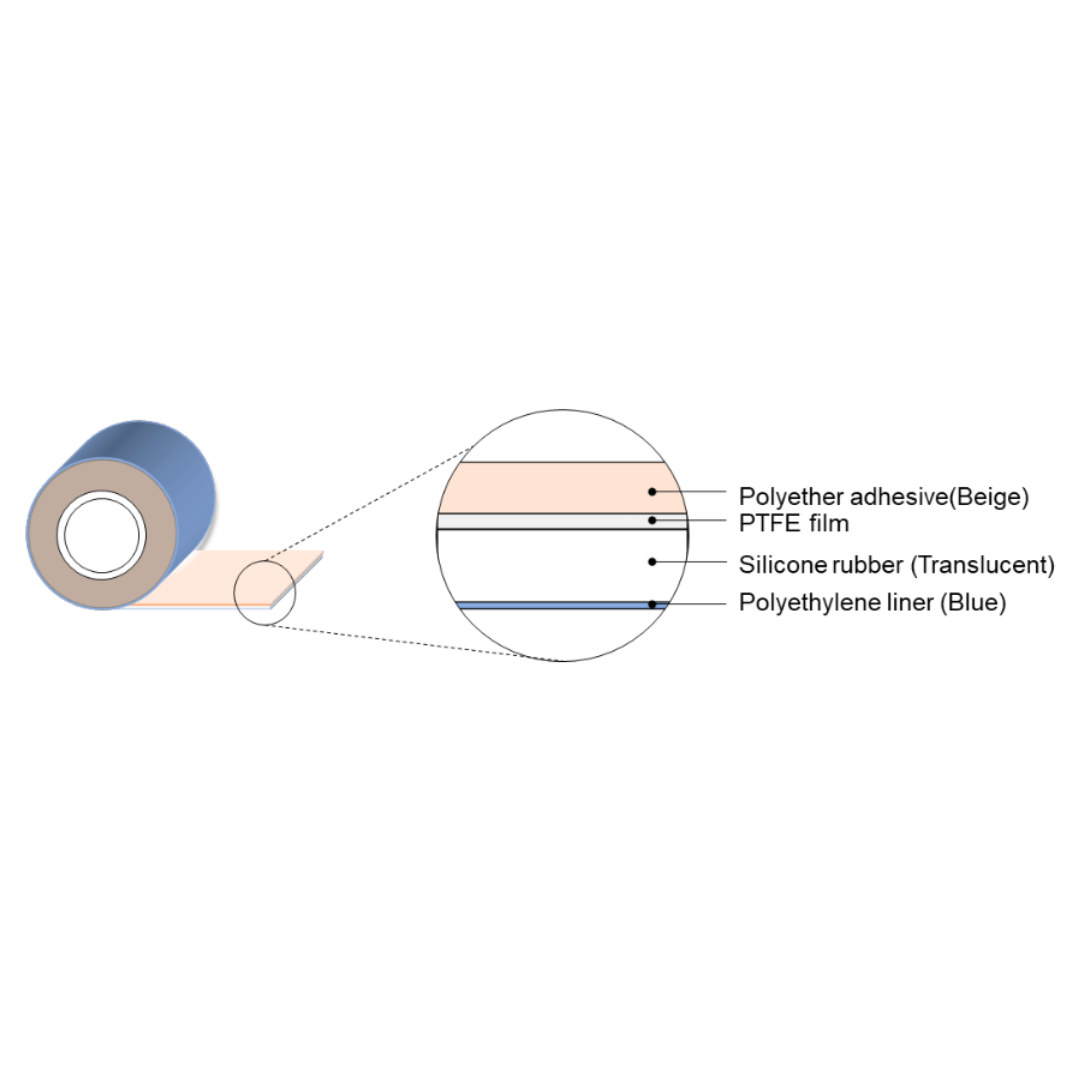

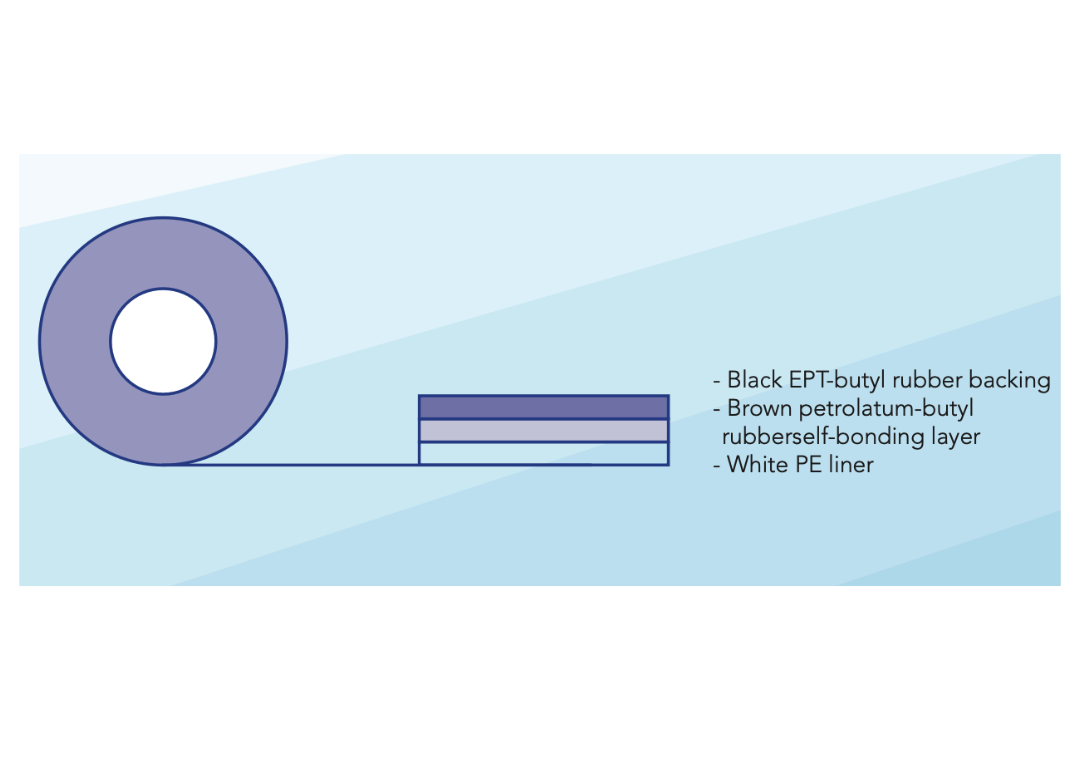

| Construction | 16 mil polyurethane + 2 mil adhesive |

| Application Method | Two-part (seams first, full panel coverage after) |

| Resistance | Puncture, tear, and chemical resistant |

| Vapour Barrier | Low water vapour transmission rate |

| Flame Retardancy | Yes |

| Elongation | High – suitable for active work areas |

| Ease of Application | Excellent – easy to reposition and apply |

| Compliance | REACH & RoHS |

Application Areas

High-Moisture Zones

Creates impermeable barriers in areas frequently exposed to water such as galleys, lavatories, and showers.

Panel Seams

Provides targeted protection at vulnerability points where floor panels meet, preventing moisture migration.

Work Areas

Protects high-traffic work zones where floor integrity is critical to long-term vessel performance.

Cold Storage

Prevents condensation damage in thermal transition zones and refrigerated storage areas.

Application Information

Two-Stage Application Process

-

1

Surface Preparation

Ensure all surfaces are clean, dry and free from dust, oil or other contaminants that could affect adhesion.

-

2

Seam Protection

Apply BARRIER TAPE first to all panel seams, overlapping at least 2-3cm on each side of the joint.

-

3

Full Panel Coverage

Once seams are secured, apply full panel coverage working from one end to another, using a squeegee to eliminate air bubbles.

-

4

Edge Finishing

Apply firm pressure around all edges and transitions to ensure a complete seal with no gaps or channels for moisture.

Frequently Asked Questions

-

How long will BARRIER TAPE last once installed?

When properly installed in typical marine environments, BARRIER TAPE provides reliable protection for up to 10 years. However, we recommend periodic inspection, particularly in areas subject to heavy foot traffic or extreme conditions.

-

Is BARRIER TAPE suitable for curved or irregular surfaces?

Yes, BARRIER TAPE features high elongation properties that allow it to conform to irregular shapes and surfaces. Its flexible design makes it ideal for application around pipes, corners, and other non-flat areas commonly found in marine flooring systems.

-

What makes the two-step application method more effective?

The two-step method targets the most vulnerable points first—the seams—with a dedicated application that creates a reinforced moisture barrier at these critical junctions. The full panel coverage then provides a continuous protective layer that integrates with the seam protection for comprehensive moisture control.

-

Can BARRIER TAPE be applied over existing flooring systems?

BARRIER TAPE is designed primarily for application directly to structural panels before final flooring materials are installed. However, in repair scenarios, it can be applied over existing systems provided the surface is properly prepared, clean, and stable. For retrofit applications, consult with our technical team for specific recommendations.

Request Product Information

Get detailed specifications, pricing, and application guidance for BARRIER TAPE.