High-Precision, Heat-Resistant Masking Tape (Ref-MPF336)

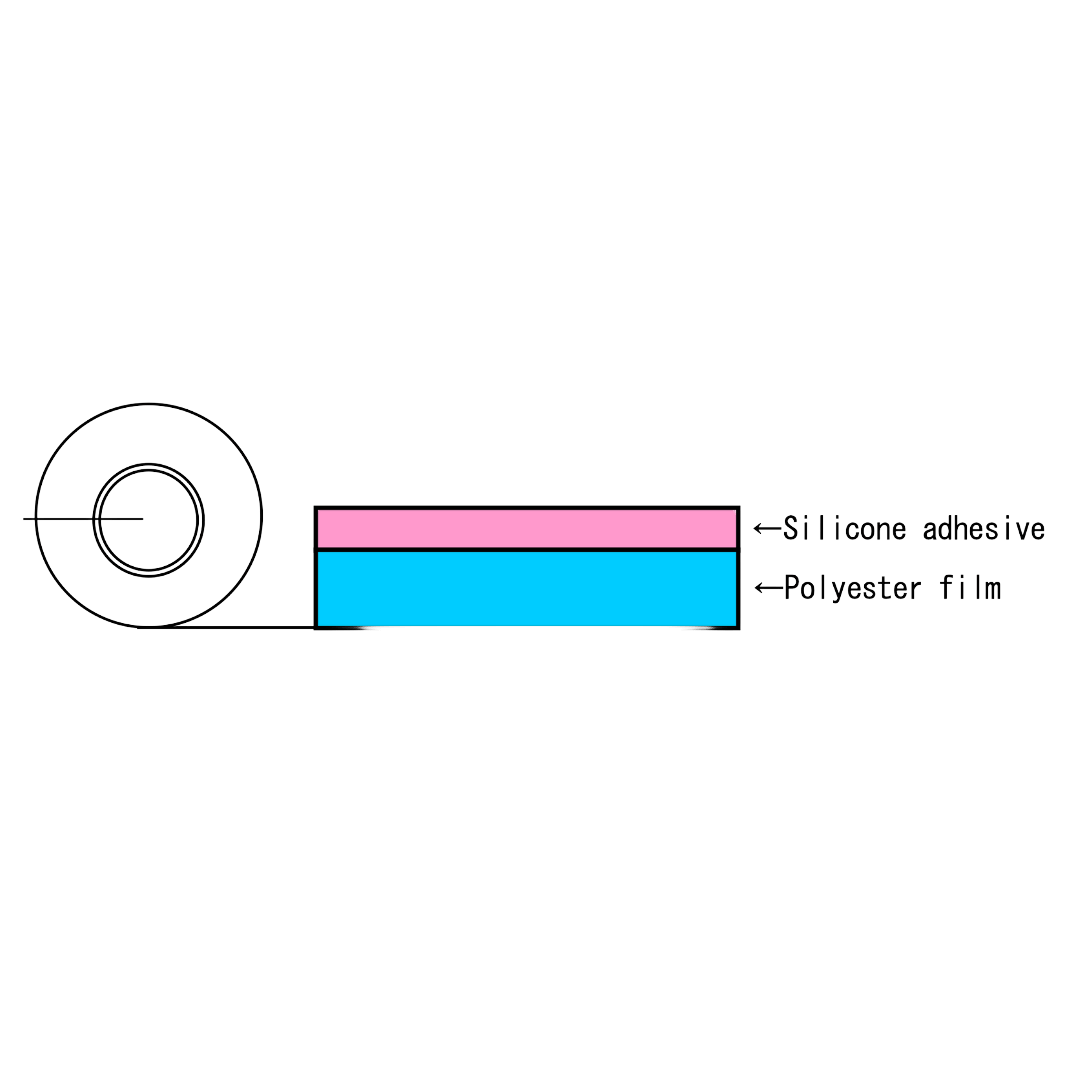

The MPF336 Filmic Masking Tape is engineered for precision plating and masking tasks that demand high heat resistance and minimal seepage. It features a thin, flexible polyester backing paired with a thick adhesive layer, ensuring clean application and reliable performance in intricate and high-temperature environments.

Ideal for plating processes, delicate marine components, and areas requiring exact masking without bleed-through, MPF336 offers superior flexibility and clean removal with no residue.

Request Product Information

Key Benefits

Heat Resistance

Maintains integrity and adhesion in high-temperature environments, ideal for industrial applications.

Precision Masking

Creates clean, sharp lines with minimal seepage for detailed plating and coating processes.

Superior Flexibility

Ultra-thin polyester film conforms to intricate shapes and tight curves without lifting or wrinkling.

Clean Removal

Peels away easily after processing with no adhesive residue, protecting delicate surfaces and finishes.

Technical Specifications

High-precision masking tape for marine plating and heat-sensitive applications

| Use Case | Indoor masking for high-precision plating and heat-sensitive applications |

| Material | Polyester film |

| Heat Resistance | Excellent |

| Weatherability/UV Resistance | N/A - Indoor use only |

| Colour | Translucent Blue |

| Ease of Application | Very Good |

| Residue After Removal | None |

| Flexibility | High – conforms to tight shapes and contours |

| Sizes | Available upon request |

Application Areas

Plating Operations

Creates precise boundaries during electroplating of marine hardware, ensuring clean transitions between plated and unplated areas.

Intricate Components

Masks complex marine fittings and hardware with irregular shapes that require detailed protection during processing.

Heat Applications

Provides reliable performance in high-temperature processes where standard masking tapes would fail or leave residue.

Specialized Finishes

Ideal for masking during application of specialized coatings and finishes that require exact boundaries.

Application Information

Proper Application For Best Results

-

1

Surface Preparation

Ensure all surfaces are thoroughly clean, dry, and free from oils, grease, and contaminants. For optimal adhesion, wipe with isopropyl alcohol and allow to fully dry.

-

2

Precision Application

Apply with gentle, even pressure, working in small sections. Use a precision tool or burnishing stick to press the tape into corners, recesses, and along curved edges.

-

3

Edge Sealing

For applications involving liquid processes, ensure all edges are firmly sealed to prevent seepage. Press down firmly on all tape edges to create a complete barrier.

-

4

Careful Removal

After processing, remove tape by pulling back at a low angle (approximately 45°), maintaining steady tension. For best results on delicate surfaces, remove while still warm from heat processes.

Frequently Asked Questions

-

What temperatures can FILMIC MASKING withstand?

The MPF336 Filmic Masking Tape is designed to withstand temperatures up to 150°C (302°F) for short-term exposure during processing operations. For continuous exposure, we recommend keeping temperatures below 120°C (248°F) to maintain optimal adhesion and performance characteristics. This heat resistance makes it particularly valuable for applications involving heated plating solutions, powder coating pre-bake processes, and other elevated temperature environments where standard masking tapes would quickly degrade, lose adhesion, or leave residue upon removal.

-

How does this tape perform with marine plating solutions?

FILMIC MASKING MPF336 has been specifically formulated to resist a wide range of chemical environments encountered in marine plating operations. The polyester backing provides excellent barrier properties against common plating solutions including nickel, chrome, copper, and brass. It effectively prevents solution creep under the masked edges, creating sharp boundaries between plated and unplated areas. The tape has also demonstrated good resistance to acid and alkaline environments typically found in marine component processing, though we recommend testing in your specific application environment, particularly for extended immersion in highly concentrated solutions.

-

How detailed of masking patterns can this tape achieve?

The exceptional flexibility and thin profile (measured in microns) of FILMIC MASKING allows for remarkably detailed masking patterns. It can be precisely cut and applied to create intricate designs with clean lines and sharp corners. The tape conforms effectively to compound curves, tight radii, and irregular surfaces common in decorative marine hardware and custom fittings. Our marine customers have successfully used MPF336 for detailed plating work on small components with feature sizes down to 1mm. For highly detailed work, we recommend using sharp cutting tools and application aids like burnishing sticks to ensure complete adhesion in fine detail areas.

-

Is this tape suitable for outdoor applications?

FILMIC MASKING MPF336 is specifically engineered for controlled indoor processing environments and is not recommended for outdoor applications. The tape lacks UV stabilizers and weatherability additives since it's optimized for precision masking during manufacturing processes rather than long-term exposure. For outdoor masking needs on marine vessels, we recommend alternatives from our product line specifically designed for UV and weather resistance, such as our Washi PREMIUM Gold tape (MPF7288) which offers excellent outdoor performance with up to 6 months of UV stability while maintaining clean removal properties.

Request Product Information

Get detailed specifications, pricing, and application guidance for FILMIC MASKING (Ref-MPF336) tape.